Forum Free Registration Closed

Forum Free Registration Closed

Granada Television Brochure, 1970s

Granada Television Brochure, 1970s

Long Gone UK TV Shops

Long Gone UK TV Shops

Memories of a Derwent Field Service Engineer

Memories of a Derwent Field Service Engineer

PYE Australia Circa 1971

PYE Australia Circa 1971

Radios-TV VRAT

Radios-TV VRAT

Fabulous Fablon

Fabulous Fablon

Thorn TX10 Chassis

Crusty-TV Museum, Analogue TV Network

Crusty-TV Museum, Analogue TV Network

Philips N1500 Warning!

Philips N1500 Warning!

Rumbelows

Rumbelows

Thorn EMI Advertising

Thorn EMI Advertising

Thorn’s Guide to Servicing a VCR

Thorn’s Guide to Servicing a VCR

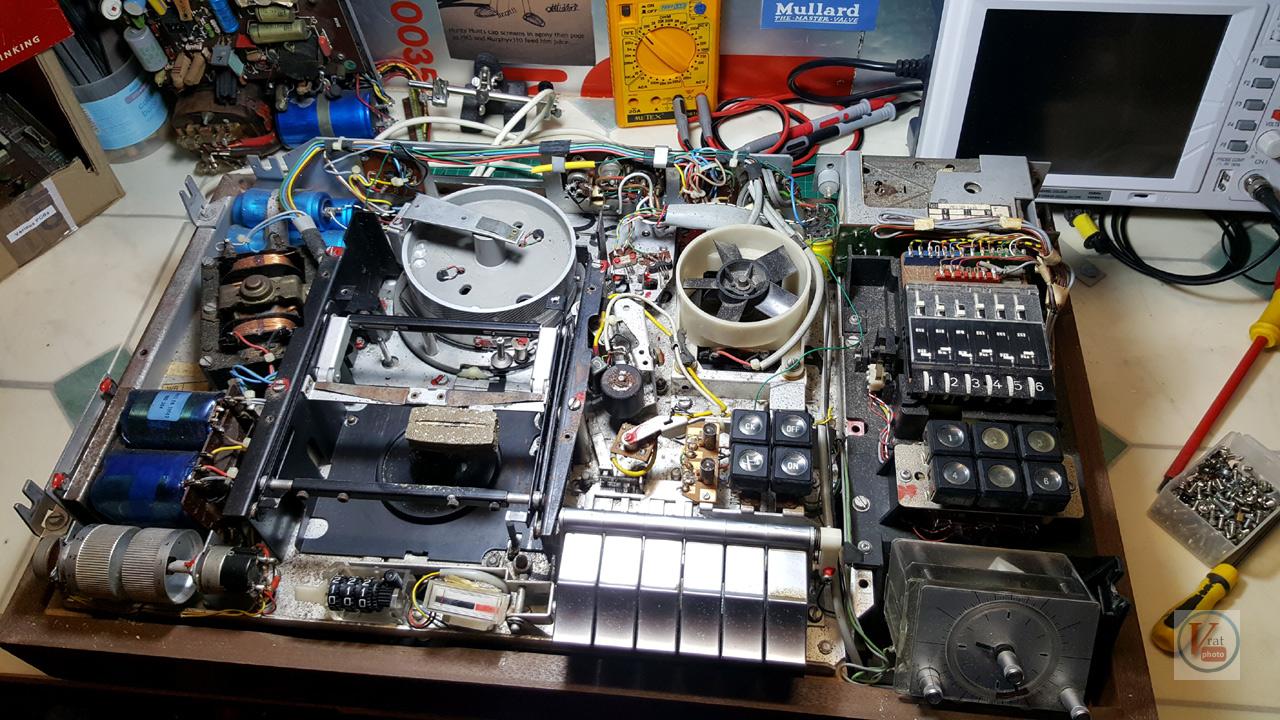

Ferguson 3V24 De-Robed

Ferguson 3V24 De-Robed

Want to tell us a story?

Want to tell us a story?

Video Circuits V15 – Tripler Tester

Video Circuits V15 – Tripler Tester

Thorn Chassis Guide

Thorn Chassis Guide

Remove Teletext Lines & VCR Problems

Remove Teletext Lines & VCR Problems

Ceefax (Teletext)

Ceefax (Teletext)

Suggestions

Suggestions

Website Refresh

Website Refresh

Colour TV Brochures

Colour TV Brochures

1970s Lounge Recreation

1970s Lounge Recreation

CrustyTV Vintage Television Museum

CrustyTV Vintage Television Museum

Linda Lovelace Experience

Linda Lovelace Experience

Humbars on a Sony KV2702

Humbars on a Sony KV2702

1972 Ultra 6713

1972 Ultra 6713

D|E|R Service “The Best”

D|E|R Service “The Best”

The one that got away

The one that got away

Technical information

Technical information

The Line Output Stage

The Line Output Stage

The map

The map

Tales of a newly qualified young engineer.

Tales of a newly qualified young engineer.

Tales of a Radio Rentals Van Boy

Tales of a Radio Rentals Van Boy

Sanyo SMD

Sanyo SMD

Disastrous Company Rebranding

Disastrous Company Rebranding

1969 Philips G22K511

1969 Philips G22K511

Memories Of The TV Trade

Memories Of The TV Trade

Crazy house

Crazy house

Dirty TV screens

Dirty TV screens

Dual Standard and Single Standard CTV’s

Dual Standard and Single Standard CTV’s

Radios-TV on YouTube

Radios-TV on YouTube

The Winter of 62/63

The Winter of 62/63

A domestic audio installation

A domestic audio installation

1979 Ferguson Videostar Deluxe 3V16

1979 Ferguson Videostar Deluxe 3V16

Music centre modifications

Music centre modifications

Unusual record player modification

Unusual record player modification

B&K 467 Adapters

Mishaps In The Trade

Mishaps In The Trade

1971 Beovision 3200

1971 Beovision 3200

Forum Free Registration Closed

Forum Free Registration Closed

Granada Television Brochure, 1970s

Granada Television Brochure, 1970s

Long Gone UK TV Shops

Long Gone UK TV Shops

Memories of a Derwent Field Service Engineer

Memories of a Derwent Field Service Engineer

PYE Australia Circa 1971

PYE Australia Circa 1971

Radios-TV VRAT

Radios-TV VRAT

Fabulous Fablon

Fabulous Fablon

Thorn TX10 Chassis

Crusty-TV Museum, Analogue TV Network

Crusty-TV Museum, Analogue TV Network

Philips N1500 Warning!

Philips N1500 Warning!

Rumbelows

Rumbelows

Thorn EMI Advertising

Thorn EMI Advertising

Thorn’s Guide to Servicing a VCR

Thorn’s Guide to Servicing a VCR

Ferguson 3V24 De-Robed

Ferguson 3V24 De-Robed

Want to tell us a story?

Want to tell us a story?

Video Circuits V15 – Tripler Tester

Video Circuits V15 – Tripler Tester

Thorn Chassis Guide

Thorn Chassis Guide

Remove Teletext Lines & VCR Problems

Remove Teletext Lines & VCR Problems

Ceefax (Teletext)

Ceefax (Teletext)

Suggestions

Suggestions

Website Refresh

Website Refresh

Colour TV Brochures

Colour TV Brochures

1970s Lounge Recreation

1970s Lounge Recreation

CrustyTV Vintage Television Museum

CrustyTV Vintage Television Museum

Linda Lovelace Experience

Linda Lovelace Experience

Humbars on a Sony KV2702

Humbars on a Sony KV2702

1972 Ultra 6713

1972 Ultra 6713

D|E|R Service “The Best”

D|E|R Service “The Best”

The one that got away

The one that got away

Technical information

Technical information

The Line Output Stage

The Line Output Stage

The map

The map

Tales of a newly qualified young engineer.

Tales of a newly qualified young engineer.

Tales of a Radio Rentals Van Boy

Tales of a Radio Rentals Van Boy

Sanyo SMD

Sanyo SMD

Disastrous Company Rebranding

Disastrous Company Rebranding

1969 Philips G22K511

1969 Philips G22K511

Memories Of The TV Trade

Memories Of The TV Trade

Crazy house

Crazy house

Dirty TV screens

Dirty TV screens

Dual Standard and Single Standard CTV’s

Dual Standard and Single Standard CTV’s

Radios-TV on YouTube

Radios-TV on YouTube

The Winter of 62/63

The Winter of 62/63

A domestic audio installation

A domestic audio installation

1979 Ferguson Videostar Deluxe 3V16

1979 Ferguson Videostar Deluxe 3V16

Music centre modifications

Music centre modifications

Unusual record player modification

Unusual record player modification

B&K 467 Adapters

Mishaps In The Trade

Mishaps In The Trade

1971 Beovision 3200

1971 Beovision 3200

A good tape would be the best thing to have.

looking at the block diagram.

U67 sync sep and disc is used with rec/playback and straight through.

U66 562.5Khz IC’s and 1:36 divider, presumably locked to the incoming sync. Used on Rec/playback

TS 602 and TS604 15.625khz pulse shaper used on Rec /playback.

I think the above is correct.

Frank

The decoder on the N1500 now seems to have developed a fault, Bubbles vest has turned pink ? here we go with Crusty's usual threads one or two steps forward then incessant steps backwards.

As for the tapes, obtaining a known good N1500 tape is not going to happen. To know if the servo is operating within normal spec, surely I just need to get the scope out and check the waveforms for the servo are as expected on the cct

CrustyTV Television Shop: Take a virtual tour

Crusty's TV/VCR Collection: View my collection

Crustys Youtube Channel: My stuff

Crusty's 70s Lounge: Take a peek

I didn't think this machine used any ICs ?, I will have to have a proper look at the diagrams, as I say I have never had anything to do with these machines.

IC's are present in T0-5 packages, mentioned this in post #6 see below

Posted By: Crustytv

I've read some incorrect online sources that state the N1500 is purely TTL. However despite the device appearing to be packed to the brim with lockfits, I have found a couple of I.C's, just not in the usual DIL package but contained within a 10 pin TO-5 package.

The first time I came across the use of these early I.C's was in the 1968 1st gen Baird M718 CTV for signals processing, I wondered at the time if it was perhaps the first use of an I.C in a British manufactured television. If you've not already seen it, I covered this type of package in an I.C. blog article you can read here.

CrustyTV Television Shop: Take a virtual tour

Crusty's TV/VCR Collection: View my collection

Crustys Youtube Channel: My stuff

Crusty's 70s Lounge: Take a peek

On record the servo seems to be locked to the frame sync pulse, are they there?

On playback it seems locked to 50hz mains. Is the mains supply clean and not full of spikes?

Frank

The head servo partly determines the speed of the frequency (FM) coming off the tape, hence the demodulated video so I wouldn't worry about the chroma off tape at this point, it will be wrong anyway, I don't think this machine is modern enough to use the chroma section as a reference for the servos like some later machines did although I will stand to be corrected. I need to have a read up on this in the tv mag article and the Dutch manuals in a lot more depth.

Hi Chris, of course I am aware of the early TO-5 ICs 🙂 just I always thought the N1500 was pure discrete components, but as I have never had anything to do with them I of course stand to be corrected.

You may be in a chicken and egg situation with trying to check servo with a 'possible' non standard recording as your means of test signals. Maybe someone with a working machine could make a recording for you to use for this purpose if you sent them a tape to use?

Jon

BVWS Member

Hi Baz I'm not talking about chroma playback off tape, I'm talking about the direct signal going from my test card gen into the VCR and being present on the video channel of the TV.

All today the vcr has been tuned into the Test card gen, it has been receiving it and displaying it correctly to the TV, now its is not. I would appear the ident or oscillator on the VCR decoder has drifted. Its not the TV as the signal when direct to the TV is colour correct, there is now a VCR decoder fault manifested. It is irrelevant as you say to the fault in hand just something else I need to tackle. I need to get to the bottom of why I'm not getting consistent sync playback.

I'm done for today, will start afresh tomorrow.

CrustyTV Television Shop: Take a virtual tour

Crusty's TV/VCR Collection: View my collection

Crustys Youtube Channel: My stuff

Crusty's 70s Lounge: Take a peek

Ah right, re: chroma you are talking about E to E (EE mode), got you.

Edit: EE = Electronic to Electronic

Hi Chris,

On this type of fault/s you really do need a known good recording, you need to sort out playback issues first before even looking into record faults (that may, or may not even be there once any servo issues are sorted) , fair enough a proper test/reference tape is probably "unobtainium" but nevertheless you still need some sort of reference to start from or else you will end up going round in circles as Jon said above ^^^, can you not put a request out for something/anything as a starting point ?

Hi Baz,

I thought perhaps mistakenly that a known, good, working N1500 tape was likely unobtainable. I suppose as you say, there's no harm in asking. Though I'm only aware of three Vratters that I can ask who have an N1500 and might have a tape or can make one. Rob's ( Vintagerob) machine is not working so doubt he knows if he has a good tape. That leaves Adrian (Hurty) and Andy (Doz).

If I cannot find a good known test tape surely that's not a show stopper?

I must be able to test and verify the expected pulses to the servo control circuit are present. That they are of the correct timings and amplitude to ensure the servo is operating optimally. If found to be sub-optimal with the aid of the circuit, scope and meter diagnose the cause and fix with that method. In the factory surely these devices were technically set up and aligned with scopes and not purely relying only on a tape or am I mistaken?

p.s.

The chroma fault is on not on the VCR as I thought, I was being a twonk. I know I'm getting tired when I start making fundamental mistakes and assumptions. The Teleton has developed the fault not the VCR. I've connected my TX9 and all is well on direct test card signal and E-E. Apologies for the misinformation, in a way pleased as it one less thing to worry about on the N1500.

CrustyTV Television Shop: Take a virtual tour

Crusty's TV/VCR Collection: View my collection

Crustys Youtube Channel: My stuff

Crusty's 70s Lounge: Take a peek

I gently tried the finger test on the top of the head drum, adding just a tiny bit of resistance, the effect of this was to consistently stop the picture from attaining any sync whatsoever. When the finger was removed the picture output reverted back to its previous state of coming and going, sometimes staying for an extended period of a good few seconds, before once again returning to its fluctuating sync state.

I guess this suggests the that drum is not attaining/maintaining its speed due to incorrect/sub-optimal eddy braking and as such consistent sync is not achieved?

As far as I can tell the drum is free running and not impeded, I'm left wondering if the circuit that controls the braking, (eddy current) is running in a sub-optimal state and how I now investigate this. This leads me right back to the question I posed a couple of days ago in the previous post to this one. That surely I should not have to solely rely on a test tape, that I should be able to investigate and rectify the speed problem with a scope and logical fault finding within the servo circuit.

CrustyTV Television Shop: Take a virtual tour

Crusty's TV/VCR Collection: View my collection

Crustys Youtube Channel: My stuff

Crusty's 70s Lounge: Take a peek

I should be able to help ... the issue is I'm not back home for a few weeks, and the machine hasn't run in a while!

"That surely I should not have to solely rely on a test tape, that I should be able to investigate and rectify the speed problem with a scope and logical fault finding within the servo circuit. "

One of the problems here is if the drum (or capstan) speed is incorrect in both record as well as playback (plausible) then it changes the track angle of the helical scan, if the head is slightly fast then the track angle will be steeper and shorter, vice versa for slow ie. longer and shallower angle, the capstan speed also changes the geometry somewhat. all VCRs are manufactured to incredibly tight tolerances (micron level), both mechanical and electrical, a scope won't be accurate enough assuming we even knew exactly what to look for, also servo systems by their very nature tend to try and correct any minor errors within their lock in window, pulling any electrical readings/adjustment off by a small amount by way of trying to compensate. if they stray outside of their pull in window they tend to fluctuate wildly and can and do go unstable, this exacerbates the problem of trying to take readings.

Jon mentioned earlier that with the servo/s somewhat out a bit you will most likely be recording a non-standard tape, even if you fixed the original fault you would not know it as the non standard recording previously made while the machine was still faulty would not play back satisfactory, this then leads to the classic "chicken and egg situation" in that you are trying to hit a moving target whilst you yourself are also moving,

I know I could not line a machine up relying on only a scope without a known good recording to work with, even if you were extremely lucky and managed to line up the machine to be compatible with itself you would probably be into lottery winning odds of getting it to be compatible with both the original standard and of course any other machine of the same format.

VCRs with faults such as this can be difficult at the best of times, even by experienced engineers, without a known good recording to start with virtually makes the task impossible.

Pure electronic systems most probably can be set up good enough with instruments, but even adjusting TVs for example you have a signal that conforms to the standard to adjust the set to, VCRs also have mechanics in the mix which complicates things by an order of magnitude especially with such fine tolerances.

As I said you really need (really 🙂 ) a known good recording as a reference point before you start.

Thanks Baz, for your detailed explanation ?

In which case It would appear I'm stuffed until I can source a "known good" N1500 recording that works on all machines and not just the source machine. Until then this N1500 repair comes to a halt, shame but I'm sure this is not where the story ends.

I'll now tackle one or both of the two Philips N1700's I've recently acquired. Both N1700 machines are DOA, no signs of life when powered on. Thankfully I have the full English Philips service manual with all the release supplements which will make life a lot simpler. Also a box full of spares and finally have test tapes with what I believe to be N1700 recordings which would appear to be essential in light of recent events.

I'll start a new thread for these in due course.

CrustyTV Television Shop: Take a virtual tour

Crusty's TV/VCR Collection: View my collection

Crustys Youtube Channel: My stuff

Crusty's 70s Lounge: Take a peek

In a reasonably ideal world Chris I would want a recording from another working N1500, also at least 1 or 2 pre-recorded tapes and try to centre across these 3, in a perfect world 😉 an alignment tape.

Number 3 is most probably impossible.

I had a similar problem years ago with the Betamax system as I was one of the few that would still repair Beta machines (up here at least) in their dying days, however I had a few half decent ex-hire pre-recorded tapes and also a few good recordings from untouched Beta machines, even though these were comparatively rare as far as VHS was concerned which I did have manufactures alignment tapes for (still have) this was far easier than the problem you are faced with, I even had a Few Philips V2000 pre-recorded tapes back then.

Ps, I never did get a Beta alignment tape though.

Thought those members who are interested in the operation of the N1500 series servo's, might find the following data gleaned from 'Television' November 1975, of some interest.

This is the area where my N1500 most likely has a fault, it will certainly do no harm to have a look at voltages and waveforms for anything glaringly incorrect, that it is operating or trying to operate as described. Even if it is pointless in light of Baz's advice, no matter how hard it tries to thwart me, I'm certainly not in the mood for giving up just yet!

The Philips N1500 Servo operations

The Servo

Before any explanation of the VCR servo can be given, a closer examination of some of its functions must be made. Two types of correction to the speed of either the tape capstan or head drum can take place. The first of these will correct for long-term fluctuations in the speed of rotation, such as may be caused by the changing amounts of tape on the two spools in the cassette producing a slow but gradual fluctuation in the tape tension around the head drum. The second type of correction will take place during a short period of time, for example to correct sync disturbances of the programme material, or very large servo errors which develop when either the record or playback modes are entered. Splices, creases and dropouts can also cause the servo to compensate for an error very quickly. Long-term errors are normally caused by changes in the mechanical conditions of the transport system itself, while short-term disturbances are nearly always caused by electronic fluctuations of either the material being recorded or replayed, or the electronics of the machine. One must always bear in mind that the prime function of the VCR servo is to reproduce during the playback mode the exact conditions that were present in the record mode.

figure 13 & figure 14

Error voltage generation

The method used in the VCR (and in many other VTRs) to produce the error voltage, which is fed via a power amplifier to the eddy current brake, is rather unusual and warrants a closer look. To generate the error voltage two signals are required. One is a reference which is known to be correct, and the second is the feedback voltage which is to be compared with the reference. The reference voltage takes the form of a saw-tooth ramp falling in a linear manner from a high potential to a low potential, see Fig. 13. This ramp is of course generated at the reference frequency, 25Hz. The feedback signal which is to be compared with the reference consists of a pulse of constant amplitude and width, but whose frequency will change with a change in speed of the head drum or capstan motors. The feedback pulse is used to gate out part of the reference ramp as shown in Fig. 14. When the servo has locked, the gate position will appear in the centre of the ramp, but should the phase of the motor change then the gate position will travel either up or down the slope depending whether the speed of the motor has decreased or increased. The sampling gate conducts during the period occupied by the feedback pulse, and the coincident portion of the ramp is removed. This is amplified and then fed to a smoothing or storage stage. A basic block diagram is shown in Fig. 15. As the phase of the feedback pulse changes then so does the gating position on the reference ramp causing the gated signal to rise or fall in potential. See Fig. 16.

figure 15 & figure 16

Servo record mode

The block diagram of the VCR servo in the record mode is shown in Fig. 17. As we have seen, during the record mode the servo reference is the field sync information contained in the video signal to be recorded. The separated mixed sync pulses are fed to a field pulse separator TS461 and then clipped by TS462 to produce a clean positive-going field sync pulse. These field sync pulses are then used to lock the master reference oscillator TS228 and TS229. It can be seen from the block diagram that the method of controlling the frequency of this oscillator is very similar to the correction system just explained. The square-wave output from the oscillator TS228, TS229 is fed to a saw-tooth generator TS230.

The output of this stage is a waveform similar to that shown in Fig. 13 and this is gated by the shaped field pulse which is applied to the sampling gate TS231. The output of the sampling gate consists of the gated portion of the ramp applied to its input, the amplitude of this gated signal being dependent on the phase of the master oscillator when compared with the reference field pulses. This error voltage is then applied across a capacitor to store the signal and convert it to the d.c. control voltage. From here the signal is d.c. coupled to an impedance matching emitter -follower and then applied to the master oscillator.

figure 17

The square-wave output of the master oscillator is fed to a binary divider TS226, 227 and from here the true reference signal is fed to three separate sections of the servo. The first of these feeds is to a pulse amplifier which drives the control track record head. It will be noted that the signal recorded does not have h.f. bias as one might expect but is simply recorded directly onto the tape. All that is required of the control track signal is that it gives an accurate reference of the moment that a new picture is recorded. The shape, or any distortion is not important. Even broadcast machines costing many tens of thousands of pounds do not go to the expense of biasing the control track signal. The second output of the binary divider is applied to the head drum servo as the reference signal and the third output is fed to the capstan servo, again as a reference.

Head drum servo

Comparison between the reference and the feedback signal needs no detailed explanation, apart from mentioning that the feedback signal is produced by passing a magnet that is attached to the head drum over a pick-up coil once every revolution of the head drum. The resulting pulse from the pick-up coil is shaped by TS201 before being used to gate the ramp. The error voltage from the storage circuit is applied to one input of a differential amplifier, the second input to this amplifier is produced by half -wave rectifying and smoothing the error voltage (D205 and C209).

The direct feed to the differential amplifier will be a d.c. voltage plus a ripple a.c. caused by the sample rate in the discriminator. The second input contains just the d.c. component of the error. Once the servo has locked the ripple voltage will fall because a constant -rate sample of the same potential is being made and then smoothed by the storage circuit. If the servo loses lock then the gate position will travel up or down the ramp producing the varying ripple voltage which is then used to produce an output from the differential amplifier. The big advantage if producing both inputs of the differential amplifier from the error voltage is that the difference between the two will always be comparatively small. Hence the servo is always inside its normal lock -in range, and is able to lock from the start of a mode with maximum speed. The output of the differential amplifier is amplified by TS212 and fed to the eddy current brake to control the speed of the head drum. The video head is now locked directly to the picture information being recorded and phased so that the field sync is being recorded at the beginning of a new scan of the tape.

Capstan servo

The techniques used in the tape -capstan servo are very similar indeed to those used with the head drum, the only differences being the introduction of a lock -in circuit between the storage stage and the differential amplifier, and the absence of a pulse amplifier in the feedback path. The discriminator is the same, in principle, as before; only the feedback signal has changed and this takes the form of a 25Hz pulse derived from a sync head on the capstan flywheel. The error signal from the storage stage TS217/220 has its d.c. component directly coupled to the differential amplifier, while the a.c. component is fed to a lock -in circuit which amplifies the a.c. error and stores it on a 10µF capacitor, producing a smoothed d.c. voltage. A portion of this voltage is added to the original error and applied to one input of the differential amplifier. The remainder of the d.c. voltage is fed via a diode limiting circuit (to prevent the servo from going outside its correction range) to the second input.

The reader will notice that up to now all the correction on the speed of the capstan servo has been long-term d.c. correction because of the slow tape speed changes required. Remember that the guard band between video tracks on the tape is very small indeed, and any rapid correction could cause the servo to overshoot the information on the tape. A small amount of a.c. correction is however applied in the form of feedback from the output to the input of the differential amplifier. The error output of the differential amplifier, is now fed via a power amplifier to the eddy current brake on the tape transport capstan motor. During the record mode the capstan and the head drum are synchronised directly to the incoming picture information. The head drum is locked in such a way that the field sync information is recorded at the beginning of each new video track, and the capstan produces a synchronised and continuous tape speed. Should the frequency of the reference field pulse shift, then both servos will compensate for the change simultaneously.

Playback mode

As we have seen earlier in the series, the servo reference in the playback mode is mains frequency, and the head drum servo locks directly to this reference once it has been processed and divided by two. Fig. 18 shows the block diagram of the machine in the playback mode; the head drum servo should need no explanation. The capstan servo is again very similar to the arrangement used in the record mode apart from the fact that the feedback signal is delayed by TS465 and TS466. This provides a method of accurately phasing the position of the tape so that the video head is scanning through the centre of the recorded information. The capstan servo feedback signal is of course the picture frequency control track.

figure 18

When both of the servos are locked in the playback mode the feedback pulse from the head drum is coincident with the mains reference, causing the video head to start its scan of the tape. The capstan has positioned the tape so that the control track pulse from the tape is again coincident with the mains reference, and hence the control

track pulse is also coincident with the beginning of the head scan across the tape. In the record mode this was the point at which the field sync information was recorded, so it can be seen that the servo has in fact reproduced the exact conditions that were present during the recording of the material.

CrustyTV Television Shop: Take a virtual tour

Crusty's TV/VCR Collection: View my collection

Crustys Youtube Channel: My stuff

Crusty's 70s Lounge: Take a peek

Posted by: crustytvNo matter how hard it tries to thwart me, I'm certainly not in the mood for giving up just yet

That's the spirit ! ?

To understand the black art of electronics is to understand witchcraft. Andrew.

Despite my lack of knowledge regarding the 1500 and 1700 I do remember something about those sync waveforms now and back in the 70's we were using pretty simple scopes (by today's standard) in the Philips workshop. I seem to recall an 'introductory' training course being given when these machines first appeared.

I reckon it would be worth checking some of those basic waveforms especially the 'known' reference signal.

-

1986 Ferguson 3V55; Boxed

9 months ago

-

1981 Sharp VC2300H & XC-30 Colour Camera

10 months ago

-

N1500 with various issues

12 months ago

-

Philips N1500 - An Adventure in Patience?

3 years ago

-

Philips LaserVision

3 years ago

- 33 Forums

- 7,940 Topics

- 116.3 K Posts

- 1 Online

- 331 Members